Precise cutting capabilities are critical to meet today’s demands for glass fabrication. Waterjet cutting machines exceed expectations with results notable for precision and accuracy.

Waterjet cutting machines are the premier option for achieving high levels of precision in glass products. Unlike alternative methods, such as flame cutting and plasma cutting, waterjet cutting provides unmatched versatility to work on many materials—including nonmetals like glass. Waterjet cutters also stand apart for utilizing abrasion versus heat to make cuts—reducing the likelihood of product damage and eliminating the risk of toxic fumes.

Aldora recognizes the clear benefits of waterjet cutting and utilizes the process for precise results in many products—shower doors, interior glass doors and custom glass, just as a few examples. This allows Aldora to accommodate a diverse range of material, thickness and timeline needs from architects and contractors, beyond the scope of other cutting processes. Aldora has waterjet equipment in all seven locations to ensure a high quality product to the markets we serve.

How Does Waterjet Cutting Work for Glass?

In its simplest form, the waterjet cutting process leverages high-pressure erosion to cut through glass. It is helpful to think about it as a form of liquid sandpaper, whereas other cutting options utilize ionized gas, laser light beams and electrical discharges for cutting – in other words, heat.

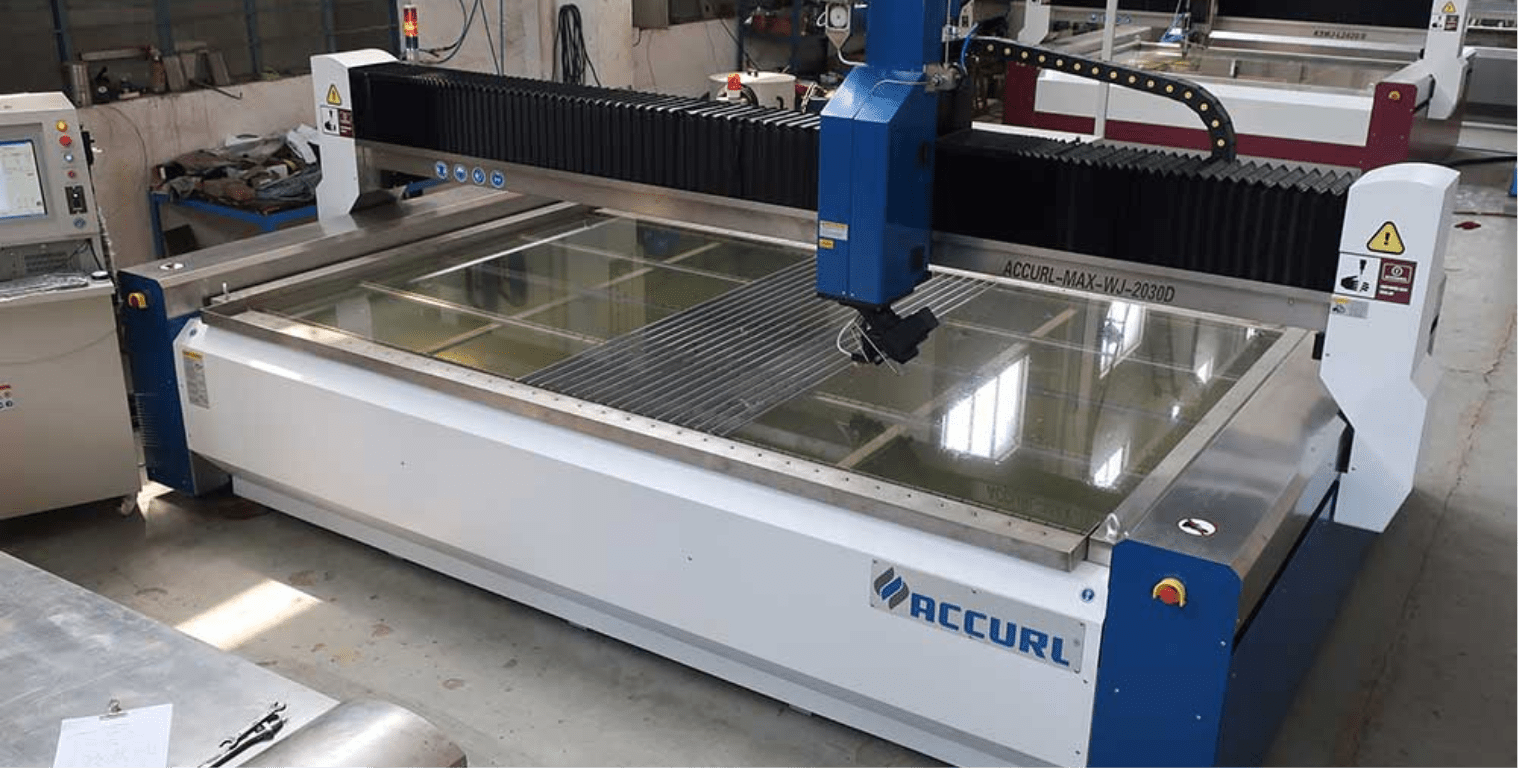

The waterjet glass cutting machine uses a mixture of water and abrasive material — such as sand or garnet — to effectively penetrate materials. The mixture is pressurized in a mixing chamber and then ejected through a nozzle that travels across the material it is used to cut. A catcher tank underneath captures the solution and energy transmitted during the process.

When Should You Use Waterjet Glass Cutting Machines?

Glass fabricators should use waterjet cutting for projects that involve precise cutting, unique materials or to reduce the risk of damage. Precise cutting is especially useful for intricate architecture, uncommon shapes or when holes for hardware are required—such as spaces to fit handles. Waterjet cutting leaves a smooth, satin edge without the risks of distortion or damage from other methods. These machines can also handle thicker materials than other equipment, lessening risk to damage the finished product.

Whether using waterjet cutters for precise or unique projects, the machines offer substantial protection from damage—making them an exceptional choice for glass fabricators. Whether seeking sharp corners, beveled edges, piece holes or complex designs, waterjet cutters consistently deliver high-quality returns.

Five Steps of Glass Waterjet Cutting Process

There are several important considerations when using a waterjet cutter for glass projects. Here are the main steps taken by Aldora experts during the waterjet cutting process:

1) Our team determines glass size, thickness and cuts to be made.

2) We set machine controls to meet these unique specifications.

3) We make sure water and abrasive material is filled properly in the machine.

4) Our team starts the waterjet glass cutting machine and monitors performance.

5) We examine results and make sure products meet builders’ expectations.

Experts at Aldora are highly trained to operate waterjet cutters for optimal results. By understanding project needs, Aldora helps builders achieve their design needs.

Consider Aldora’s Waterjet Cutting Services

Waterjet glass cutting services from Aldora offer first-rate solutions to meet increasing demands. No detail is too small or project too intricate for our machines. Our experienced team works diligently to produce customized results for each builder’s unique needs. By utilizing waterjet cutters, Aldora provides top-tier precision.

Prevent hassles and mishaps by working with Aldora for premium results. Waterjet cutting produces superior cutting outcomes compared to competitor machines. With service from Aldora, builders can feel confident with timeless products.

Aldora Uses Waterjet Cutting for High-end Results

From shower doors to glass tabletops and beyond, Aldora takes advantage of the benefits of waterjet cutting to produce premium design solutions for customers. Partner with us today.

Prev

Prev